The application of supply chain concepts is extensive and quite different from sector to sector. This report is written in the context of the oil & gas sector in the Middle East. This sector is dynamic and vital to the growth and prosperity of Middle Eastern countries. International economic and political scenarios significantly impact this sector. Most oil & gas companies in the Middle East are international firms operating, providing oil exploration & development services, and using the latest technological tools. However, in many cases, information gathered at one data point is not available across all the functions and is contained in functional silos instead of a wholly integrated information platform encompassing the whole organization. The oil & Gas sector can come forward with a digitalization drive and develop global regulatory standards for implementation across the industry worldwide.

1. Development of the Supply Chain structure Over the past five years: Globalization, Consolidation, and Integration

Over the past few years and with the advancement of globalization and the development of information technology, the world is more connected than ever before, and the supply chain has transformed from just a localized function of procuring and distributing things to a complex network of suppliers and service providers by taking advantage of competitive global networking. Today’s supply chain has more inter-dependencies with its partners and is greatly affected by the politics and international events in other parts of the world. [i]

With global reach and expertise available, companies are extensively adopting outsourcing to their advantage. Outsourcing means engaging other companies that have gained expertise in a specific field of operations through their repetitive experience rather than utilizing in-house resources for the same services. While becoming competitive, the global supply chain is increasingly complex, as illustrated in the diagram where the procurement teams buy equipment worldwide. Placement of orders is easy with the help of Internet technologies. [ii]

“Two examples from leading global brands illustrate the complexity of today’s global supply chain ecosystems:

- Apple’s iPhone 6 supply chain involves 786 suppliers in 31 countries, 60 in the United States, and 349 in China.

- Boeing’s extended global supply chain procures 783 million parts per year, involving a total spend of $28 billion, across 5,400 factories employing 500,000 people.”

As a function, the supply chain’s responsibility is to avoid business risks due to globalization, interconnectivity, and interdependencies. One feature to avoid global risk impacting the business is becoming agile and efficient in running SCM functions. This is possible only when the supply chain connects with suppliers beyond Tier 1 partners and reaches the following levels of connectivity. [iii]

Tools of Connectivity:

Adopting new technologies can help ease the cost pressure that industries face today. Due to similar exercises in the past, relying solely on cost negotiations with service providers has become ineffective. With fewer margins left by the service providers, they cannot offer more discounts or straight cost cuts.

Should the supply chain give up on reaching new levels of cost excellence as a function? The answer is no. The alternative solution is to be innovative and realize cost efficiencies using the latest technologies, which can be vital to achieving operational, organizational, and cost efficiencies.

The APICS Dictionary, 16th edition, defines Supply Chain visibility as follows: –

“Supply Chain Visibility – Sharing information throughout the supply chain to create transparency among supply chain partners; for example, the ability of supply chain partners to access demand and production information from trading partners.”

Better connectivity brings more comprehensive supply chain visibility for a robust management decision-making process. Digital transformation is not merely installing good Enterprise Resource Planning (ERP) software. Instead, it connects all data collection points across supply chain functions and presents the information in an understandable/presentable format to eliminate any inefficiency in the processes. Also, real-time and better connectivity has brought in a higher level of indiscrimination and transparency. [iv]

There are multiple tools available today for better visibility.

- Sales and Operational Planning (S&OP)

- Warehouse Management System (WMS)

- Transport Management System (TMS)

- Mobile Computing

The Way Forward:

A digitalized supply chain is the way to bring in cost efficiency compared to eliminating/compromising services or always focusing on cost reductions. The oil & gas sector is going through tough times due to the pressure of reduced oil prices. Numerous job cuts exist, and new projects with capital spending are reduced. Oil & Gas operators are reluctant to spend more money on either innovation & trying new technologies or new exploration wells. However, there are numerous ways the oil sector can benefit from digital transformation, get instant data collection at the warehouse and logistics operations, or become more efficient with lean inventory levels. [v]

From a regional perspective, the Middle East depends heavily on its exports of oil & gas resources. The world’s demand for crude oil is 90MM barrels per day, nearly 6MM barrels less than the previously forecasted numbers for 2020. The projections for the coming five (5) years are also slow due to the ongoing coronavirus and its impact on global oil prices. The Middle Eastern oil sector is susceptible to worldwide oil prices and reacts violently to the sharp changes in oil prices. Most Middle Eastern oil companies depend heavily on oil equipment imports, with long lead times and complex & outsourced logistics management. [vi]

During 2017-2020, oil prices have declined from an average of US$ 80/bbl. To US$ 40/bbl. And the future forecast for 2020-21 oil price is also not very optimistic beyond US$ 50/bbl. Although most of the big oil companies in the Gulf Cooperation Council (GCC) use all modern-day technologies and are connected through Enterprise Resource Planning (“ERP”) systems, there is still much more potential for a more digitalized supply chain function that is efficient, proactive and cost-effective to meet the challenges of reduced oil prices. [vii]

The oil & Gas sector in the Middle East is somewhat digitalized, but the coordination and useful availability of information are lacking at SCM levels. A steps strategy to enhance digitalization is proposed as follows: –

- Stage 1—Digitalization: Commit at the top corporate levels to enhancing digitalization across SCM. At this stage, a gap analysis can be conducted to identify shortcomings.

- Stage 2—Agile & Lean: In this stage, processes and information flow are systematically assessed to eliminate redundancies and waste. The objective is to save time and become proactive and efficient by improving response times and making quick decisions.

- Stage 3 – Digital Ecosystem: This stage presents a coherent interaction where all organizational elements contribute synchronized. Transparency is enhanced with little resistance to adaptability, eventually giving rise to a completely digitalized environment and comprehensive supply chain ecosystem.

Figure 2 – https://www.researchgate.net/publication/319231399_Digitization_in_the_Oil_and_Gas_Industry_Challenges_and_Opportunities_for_Supply_Chain_Partners#pf2

2. Role of logistics clusters to alleviate the demand amplification (bullwhip effect)

Transportation, warehousing, and distribution are essential to the logistics equation and contribute to the manufacturers’ final price of goods and services. With the development of international trade and the creation of vital trading hubs like Singapore, Dubai, Rotterdam, Panama, Shanghai, etc., associated logistics partners have also concentrated on these critical locations, giving rise to the collection of like-companies in the same place, termed as clusters. In contrast, logistics clusters refer to the accumulation of logistics companies in transporters, distributors and storage providers, and other associated service providers in geographical hubs close to their customers. Similarly, supporting infrastructure like highways also plays a vital role in the success of logistics-related hubs and clusters.

Logistics clusters are experts in providing specialized services and are considered much more efficient in in-service delivery and cost-efficiency. Cluster companies benefit from the presence of support services in nearby locations. For many manufacturers, logistics clusters also provide value-added services and save time, money, and resources.

One example is the presence of Toshiba laptop service technicians in UPS facilities in the US. They promptly provide their customers with repair services and ship the products back to customers without much time.

Like other businesses, the logistics clusters develop, grow, and decline with global economic, political, and regional changes. Overall, with the boost in global trade volume, the vitality of logistics clusters is growing in terms of their importance, concentration, and effectiveness. Core success factors remain cost efficiency, avoiding time delays, overall transportation costs, handling logistics for complex shipments, and regional/global political risk factors.

Evolving technologies (equipment and information systems) are lifelines for logistics clusters and provide tools for reducing cargo handling times and improving service delivery at the lowest cost possible. [viii]

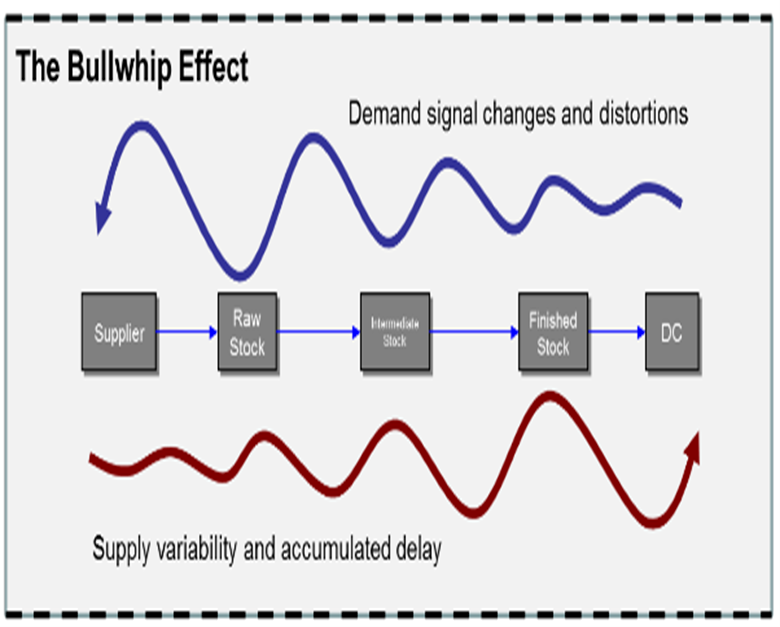

The APICS Dictionary, 16th edition, defines the bullwhip effect as follows: –

copyright (c) 2015, Demand Driven Institute. All rights reserved

“Bullwhip Effect–An extreme change in the supply position upstream in a supply chain generated by a small change in demand downstream in the supply chain. Inventory can quickly move from being backordered to being excess. This is caused by the serial nature of communicating orders up the chain with the inherent transportation delays of moving products down the chain. The bullwhip effect can be eliminated by synchronizing the supply chain”.

In a forecast-driven supply chain model, customer demand forecast is based on sales anticipations and triggers the manufacturer’s production schedule without receiving customer orders. The demand forecast is amplified over the supply channels until the manufacturer meets expected customer demands and avoids stock-outs. Since there are no existing demand orders, amplified production results in piling up inventories with stuck-up working capital, inventory redundancies, and wastage of resources; later, these inventories are eliminated by offering price cuts, discounts, etc.

An example is Cisco, which disposed of US$2.25 billion worth of useless inventory when the dot-com bubble burst at the beginning of the millennium. End-of-season sales for clothes and departmental stores are another way to clear out inventories. Promotional sales on older stocks of computers or mobile phones also reduce inventories.

What Causes Bullwhip:

Some of the reasons for the wrong demand forecast are as follows: –

- Batch ordering – restricted by the manufacturer to place orders in a set of a certain quantity

- Periodic Ordering – Placing orders restriction before completing a specific duration

- Number of Orders – No. of orders restricted by the manufacturer (like one, two, or three in a month or quarter)

- Periodic ordering (placing orders at the end of the month, quarter, etc.)

- Logistics Costs – The distributor stops order placement to meet logistic partner demand and to optimize overall logistics costs and convenience

- Any demand-forecast algorithm glitch that captures seasonal/periodic sales for higher demand projection [ix]

How to Avoid Bullwhip:

Correct information availability and visibility through automated inventory management systems can help manufacturers avoid demand forecast faults and decouple excessive demand at the distribution level without impacting scheduled manufacturing schedules.

A lean manufacturer associated with an agile logistics network is better positioned to avoid the bullwhip effect through a dynamic analysis and verification process for the customer demand forecast without compromising customer relations. It can expedite shipments when necessary to capitalize on any excess business opportunity. The key to success is enhanced communication in an integrated forecast modelling system between manufacturers, logistic partners, and distributors under shared values. It can resolve complex, messy, and unstructured demand issues and still pay back in a short time. [x]

Bullwhip in Oil & Gas Sector:

A bullwhip is not unreal in the oil & gas industry. In a typical scenario, the Oil & Gas operator company will procure bulk drilling equipment (drilling hangers, for instance) to address the anticipated well count and avoid any material shortage in the coming year. However, at the beginning of the year, crude oil prices dropped. Company stakeholders decided to revise/reduce the yearly well count by 30% and abandoned all-new appraisal & exploration well campaigns. This change resulted in redundant drilling equipment inventory worth millions of dollars. The company’s other operations also bought extra material for maintenance and operations. Last year’s inventory orders arrived early in the subsequent year and ended up in the company warehouse as unwanted, causing additional inventory holding and carrying costs.

3. Contribution of technologies to enhance connectivity and improve overall supply chain performance.

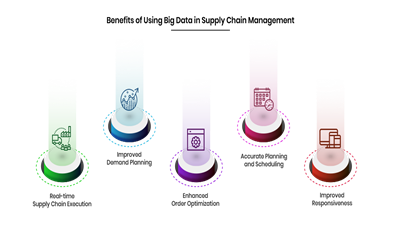

Big Data Analytics – In a large-scale business organization, multiple departments create thousands of data records at data entry points. Data is processed using big-data analytics to process these massive data records into useful information. For a supply chain department, big-data analytics help create information for different organization levels like operations, management, and executive management according to the requirements of their roles. In a typical business environment, information flows in both directions, upstream to downstream and downstream to upstream, and businesses in a particular sector adjust according to customer demands and expectations. Although fluctuations in customer expectations are minimal in the Oil & Gas sector, big data analytics still analyze and continuously monitor the complex operational environment of oil production.

Benefits of Big-Data Analytics:

In the general context of Supply Chain, big-data analytics brings the following benefits to the business: –

- Improvement in product or service delivery time.

- Eliminate or reduce the communication gap between supply chain functions

- Show relevant reports for different organizational levels

- Provide real-time information to avoid any decision-making delays

- Helps to achieve cost competitiveness and overall operational efficiency

- Better response time to meet customer needs

- Making the supply chain agile/lean with improvements in inventory holdings.

- Better e-commerce and internet connectivity enhance customer satisfaction and improve customer relationship management.

- Enhanced demand planning, inventory forecast, and efficient warehouse management

No more working in silos; all supply chain functions work coherently to achieve success and enhanced performance. [xi]

Figure 3 – https://erpsolutions.oodles.io/bl og/big-data-in-supply-chain/

The Internet of Things (“IoT”) relates to all devices that can be connected through the Internet for business benefit. A combined IT platform must join devices and produce a network with numerous access points that generate valuable information for the supply chain. The user interface generates useful information (intelligence gathering, surveillance, location tracking, and delivery information) for better efficiency at a lower cost.

Many user interfaces are now offering their group services, which include a range of data gathering and processing, to gain maximum market share and business volume. The need is to create a standard software platform that is interconnectable to customer choice. [xii]

Figure 4 – https://www.wired.co.uk/article/internet-of-things-what-is-explained-iot

Credit – iStock / Askold Romanov

- Modern-day maps are good examples of IoT, where all the world’s locations are mapped and can be accessed by the user on his mobile device or computer.

- Another example is the “Find my Mobile” option on mobile phones, which detects GPS location and closely identifies mobile whereabouts. The same applies to remote switches on/off your car.

Some IoT products, especially related to users’ personal information, may cause privacy issues. These days, many companies offer their software applications for free but seek certain privacy privileges before their use. So the information gathered from the extensive use of an application has become an asset. Many service providers use this phenomenon to their advantage and trade user privacy as a bargaining tool for enhancing their business value. IoT can also manipulate political or economic preferences and persuade in a particular direction with targeted marketing and advertisements.

- In the business world, Amazon extensively uses IoT to process its daily orders and manage warehouse functions through robotics and self-serving services instead of relying on human interaction.

- Tesla/google introduces driverless cars through cameras, radar, ultrasonic sensors, and computer-automated software. Once successful, it might be computers operating long-haul trucks under harsh weather conditions while fully synchronized and connected on a real-time basis to central computers. The Supply Chain process of that time will be immensely different and free from human error or judgment. [xiii]

- “Robotic Drilling Systems is developing a fully electric and robotic drill floor for fast, seamless, and fully unmanned operation of pipes and tools.”

- “Repsol has collaborated with IBM to bring cognitive computing to its upstream business. Cognitive technologies can ingest varied data sets more fluidly and carry out target analysis and simulation, thereby reducing the risk of these operations”.

- “Schlumberger is piloting the use of wearables based on Google Glass to improve the safety and productivity of its field employees.” [xiv]

Omnichannel—New technologies like Omnichannel and Artificial Intelligence (“AI”) enhance customer satisfaction and interaction by offering specific customizations to each customer. Omnichannel and AI realize and accept social media’s power and change the technological environment, transforming communication from unilateral to interactive.

Digitalization of the supply chain and modern-day technologies help analyze massive data created daily and convert them into an understandable format that allows for making proactive decisions for the betterment of the business. In addition, technology helps reduce inventory costs, run the warehouse efficiently, and optimize the overall transportation & logistics costs. The availability of real-time customization supported by big data analytics through the internet and Omnichannel & IoT helps improve delivery terms, reduce time to operations, and favorably improve cost optimization drives. Also, SCM digitalization brings efficiency through operational time/cost improvements and overall transparency without compromising profitability. [xv]

“To be successful, digital projects must be tied to other business projects linked to the corporate strategy and have a financial goal. For example, a project team could explore new demand planning tools to improve inventory. Similarly, a team might explore utilizing express bidding and crowdsourcing tools to reduce freight costs. Or as part of a plant reliability initiative, a team could test the use of IoT devices to help prioritize maintenance tasks”.

4. Conclusions

In conclusion, SCM digitalization is not just a goal post to achieve. Rather, it’s a continuous process improvement and mindset change to improve operational performance through modern digital means. The first thing required to achieve our goal is to make a corporate-level decision to show the extent of willingness and adoption of digital change. A gap analysis can determine where the organization is now compared to where it intends to reach using digital processes. A cost-benefit analysis is required to find out the later effects of the program and to measure the program’s success. Digital implementation occurs across supply functions to have proactive, collaborative, and predictive programs rather than troubleshooting and firefighting. SCM digitalization is all about collaborating, ease of working, a better working environment, transparency, cost and operations optimizations, and overall, a change of culture to accept digitalization as a way of work practices.

5. List of References

[i] Morana, Joëlle, and Joëlle Morana. Sustainable Supply Chain Management, John Wiley & Sons, Incorporated, 2013. ProQuest Ebook Central, http://ebookcentral.proquest.com/lib/salford/detail.action?docID=1187171.

Created from salford on 2020-10-12 21:41:09

[ii] ezdur, A. and Bhattacharjya, J. (2017). Digitization in the Oil and Gas Industry: Challenges and Opportunities for Supply Chain Partners. [online] https://www.researchgate.net. Available at: https://www.researchgate.net/publication/319231399_Digitization_in_the_Oil_and_Gas_Industry_Challenges_and_Opportunities_for_Supply_Chain_Partners [Accessed 15 Oct. 2020]

[iii] Millar, Mark. Global Supply Chain Ecosystems : Strategies for Competitive Advantage in a Complex, Connected World, Kogan Page, Limited, 2015. ProQuest Ebook Central, http://ebookcentral.proquest.com/lib/salford/detail.action?docID=2059105.

Created from salford on 2020-10-12 22:26:56

[iv] Yasmeen Hassoun (2017). How has Technology Changed the Supply Chain? [online] Obs-logistics.com. Available at: https://www.obs-logistics.com/blog/how-technology-changed-supply-chain [Accessed 13 Oct. 2020].

[v] Caudell, D. (2017). Digital Supply Chain Innovation Could Unlock Oil & Gas Industry’s New Potential. [online] www.rfgen.com. Available at: https://www.rfgen.com/blog/digital-supply-chain-innovation-could-unlock-oil-gas-industrys-new-potential

[vi] Meredith, S. (2020). OPEC cuts 2020 oil demand forecast, trims 2021 outlook on pandemic fallout. [online] CNBC. Available at: https://www.cnbc.com/2020/09/14/oil-and-coronavius-opec-cuts-2020-demand-forecast-trims-2021-outlook.html#:~:text=In%20a%20closely%2Dwatched%20monthly [Accessed 13 Oct. 2020].

[vii] Exarheas, A. (2020). EIA Cuts Oil Price Forecast. [online] www.rigzone.com. Available at: https://www.rigzone.com/news/eia_cuts_oil_price_forecast-08-oct-2020-163507-article/ [Accessed 13 Oct. 2020].

[viii] Sheffi, Yossi. Logistics Clusters : Delivering Value and Driving Growth, MIT Press, 2012. ProQuest Ebook Central, http://ebookcentral.proquest.com/lib/salford/detail.action?docID=3339501.

Created from salford on 2020-10-14 11:20:10.

[ix] Rushton, Alan, et al. The Handbook of Logistics and Distribution Management : Understanding the Supply Chain, Kogan Page, Limited, 2017. ProQuest Ebook Central, http://ebookcentral.proquest.com/lib/salford/detail.action?docID=4775023.

Created from salford on 2020-10-14 12:31:55.

[x] Contemporary Operations and Logistics : Achieving Excellence in Turbulent Times, edited by Peter Wells, Springer International Publishing AG, 2019. ProQuest Ebook Central, http://ebookcentral.proquest.com/lib/salford/detail.action?docID=5755797.

Created from salford on 2020-10-14 12:50:51.

[xi] Dutt, A. (2019). Benefits of Using Big Data in Supply Chain Management Solution. [online] https://erpsolutions.oodles.io/. Available at: https://erpsolutions.oodles.io/blog/big-data-in-supply-chain/ [Accessed 15 Oct. 2020]

[xii] Burgess, M. (2018). What is the Internet of Things? WIRED explains. [online] Wired.co.uk. Available at: https://www.wired.co.uk/article/internet-of-things-what-is-explained-iot [Accessed 15 Oct. 2020]

[xiii] Bunz, Mercedes, and Graham Meikle. The Internet of Things, Polity Press, 2017. ProQuest Ebook Central, http://ebookcentral.proquest.com/lib/salford/detail.action?docID=5166455.

Created from salford on 2020-10-15 14:00:23

[xiv] World Economic Forum & Accenture (2017). Digital Transformation Initiative – Oil and Gas Industry (In collaboration with Accenture). [online] https://reports.weforum.org/, Switzerland: World Economic Forum, pp.3–28. Available at: https://reports.weforum.org/digital-transformation/wp-content/blogs.dir/94/mp/files/pages/files/dti-oil-and-gas-industry-white-paper.pdf [Accessed 16 Oct. 2020]

[xv] Kochar, A. (2019). Digital supply chain transformation: Taking the first step. [online] www.supplychainquarterly.com. Available at: https://www.supplychainquarterly.com/articles/2061-digital-supply-chain-transformation-taking-the-first-step [Accessed 16 Oct. 2020]